Infinite Socket TF

Background

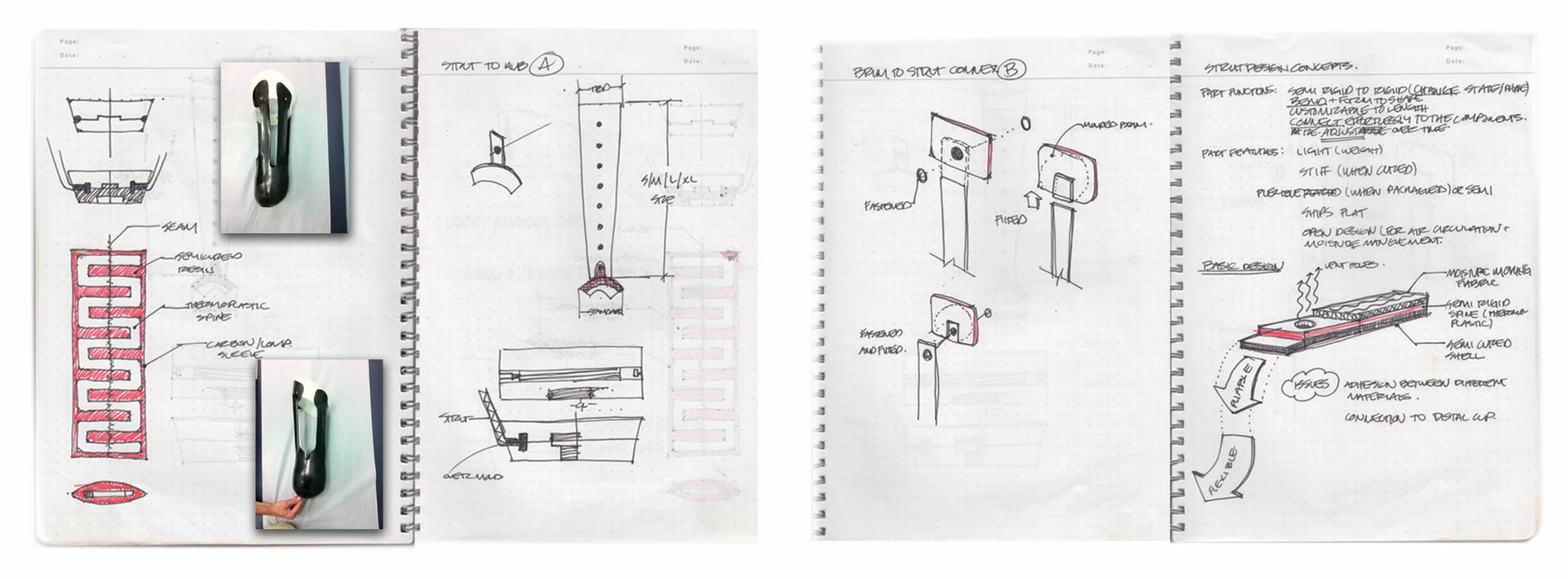

The challenge: to create an anatomical/modular fit system for lower extremity amputees in a traditional industry that resists new companies with innovative thinking. With great leadership, a solid support structure that encouraged our smart ideas, and a world class work ethic, our lean RnD team created the world’s first adjustable, custom-molded modular socket made of a carbon fiber frame and a two-part tensioning system that can be adjusted by the user.

TARGET USER

Amputees are dependent on a system that demands multiple office visits for initial fitting and follow up adjustments. Moreover, the final product may take months to fabricate and is not adjustable to accommodate their changing limb shape and size. This results in high amputee dissatisfaction with the fit and comfort of the socket and is one of the key reasons for prosthetic device failure or abandonment. This leaves the amputee unhappy and disillusioned regardless of gender, weight, or activity level.

Every aspect of the Infinite Socket TF was designed and engineered with comfort and lifestyle in mind. It mimics human anatomy to provide improved function adjustability.

The Ultimate Wearable

The most comfortable and adjustable custom socket for above-knee amputees. Every aspect of the Infinite Socket™ TF was designed and engineered with comfort and lifestyle in mind. Inspired by the design and manufacturing of bicycle saddles, the socket mimics human anatomy to provide improved function, adjustability, and comfort. The Infinite Socket™ TF adjustable components enable both patients and clinicians to fine-tune fit for better comfort and control. A modular frame and carbon fiber struts make it easy for prosthetists to make modifications in response to body fluctuations.